Introduction

This lab involves the creation of a microfluidic system. At its heart, microfluidics is essentially standard plumbing, just at a much smaller scale. Unlike plumbing, however, the liquid flowing through the channels is used to run some computation, rather than the liquid itself being useful for anything.

In this lab, we use silicone over a mold to produce the small channels. A syringe can be used to pump liquid through the channels.

Procedure and Results

- Empty mold. Dark areas are raised slightly, which produce channels in the molded silicone.

- Aluminum foil is placed in the petri dish.

- …and then cut. This allows the silicone to be removed easily.

- Silicone (pre-mixed with the curing liquid) is poured into the mold.

- The dish is placed in a vacuum chamber.

- Vacuum is applied to remove air from the silicone.

- Just a few bubbles left…

- After vacuum, most of the air has been removed.

- The dishes are placed in an oven and left overnight to cure.

- Cured silicone, after removing from the dish.

- The silicone is cut into square pieces.

- Isopropyl alcohol wash.

- Resultant pieces.

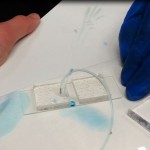

- Small holes are punched into the input/output of the channels.

- The block of silicone is secured to a slide.

- A syringe is used to pump liquid through the microfluidic channels. It’s unsuccessful, and the liquid breaks the metal-silicone seal.

- Even a more professional device doesn’t work first time. In this case, it seems like the liquid actually squirted out of a different hole, so maybe it did work?

- After a few attempts, the liquid finally goes through the channels and comes out of the other ends (note the beads of liquid).